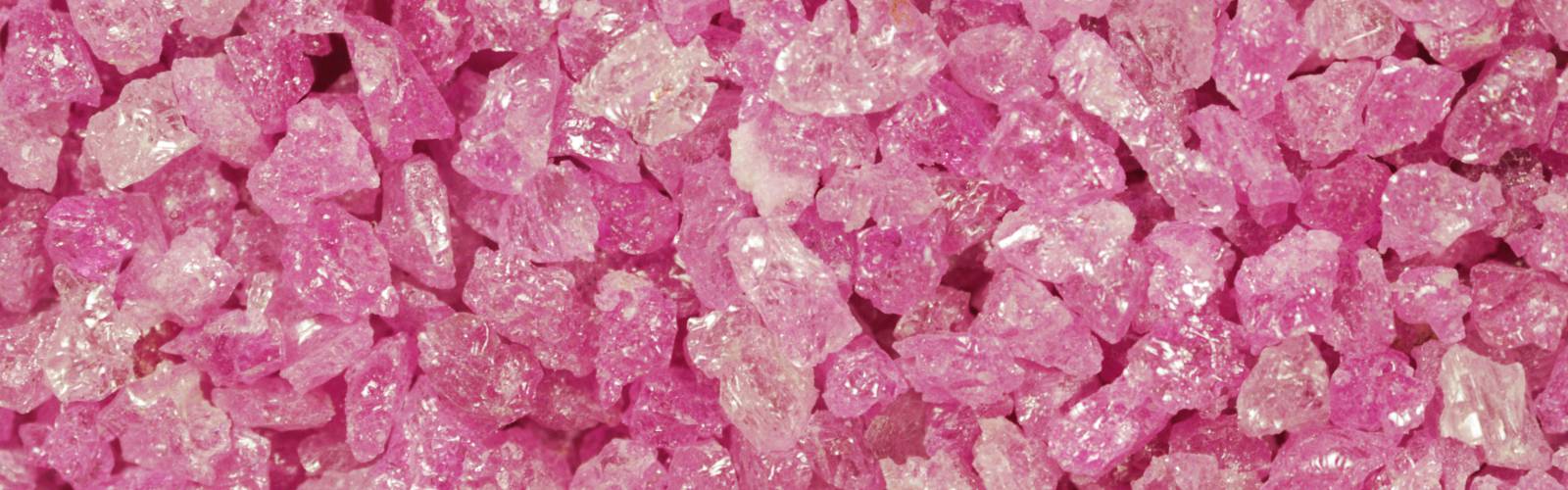

Pink fused alumina is a high-quality mineral abrasive known for its extreme hardness and particularly sharp edges. The addition of chromium oxide gives it its characteristic pink color. Pink fused alumina is produced using special high-temperature processes and is ideal for applications that require the highest precision and gentle surface treatment.

Our customers use both pink fused alumina and white fused alumina as a blasting medium and abrasive. However, the addition of chromium oxide makes pink fused alumina tougher and more durable. We will be happy to help you.

PRODUCT FEATURES

| Typical physical properties | |

|---|---|

| Hardness | 9 mohs |

| Grain shape | angular |

| Melting point | ca. 2.050 °C |

| Specific gravity | ca. 3,9 – 4,1 g/cm3 |

| Bulk density* | ca. 1,3 – 2,0 g/cm3 |

*depending on grain size

| Typical chemical analysis | |

|---|---|

| Al2O3 | 99,30 % |

| Cr2O3 | 0,30 % |

| Na2O | 0,30 % |

| Fe2O3 | 0,05 % |

| CaO | 0,05 % |

Available sizes

| FEPA

Average grain size (µm) |

|

|---|---|

| F 008 | 2000 – 2800 |

| F 010 | 1700 – 2360 |

| F 012 | 1400 – 2000 |

| F 014 | 1180 – 1700 |

| F 016 | 1000 – 1400 |

| F 020 | 850 – 1180 |

| F 022 | 710 – 1000 |

| F 024 | 600 – 850 |

| F 030 | 500 – 710 |

| F 036 | 425 – 600 |

| F 040 | 355 – 500 |

| FEPA

Average grain size (µm) |

|

|---|---|

| F 046 | 300 – 425 |

| F 054 | 250 – 355 |

| F 060 | 212 – 300 |

| F 070 | 180 – 250 |

| F 080 | 150 – 212 |

| F 090 | 125 – 180 |

| F 100 | 106 – 150 |

| F 120 | 90 – 125 |

| F 150 | 63 – 106 |

| F 180 | 53 – 90 |

| F 220 | 45 – 75 |

Other grain sizes can be produced if required.

Blasting systems

Pressure blast machines

Vacuum blast machines

Packaging

25 kg bags on 1t pallets

1 ton loose in a big bag

APPROVAL

CSS12 (Rolls-Royce)

SPECIFICATION

FEPA F

FEPA P

EN ISO 11126-7

DIN ISO 8486-1

MIL A-A-59316

ANSI B74-12

JIS R6001

D50TF5 Class A+D

Why choose pink fused alumina from Kuhmichel?

Kuhmichel provides not only a high-quality abrasive but also comprehensive customer support with tailored solutions to ensure your project is executed precisely and efficiently.

- Experience and Expertise: Decades of specialization and technical know-how to achieve the best results.

- Certified Quality: Our Edelkorund meets stringent ISO standards and is consistently tested for high purity.

- Optimized for Applications: Ideal for surface treatments such as grinding, sandblasting, and deburring, our Edelkorund is versatile and precise.

Key Properties

Edelkorund is a synthetic mineral that excels in high-temperature stability and chemical purity. This unique form of corundum is produced through specific processes to ensure maximum performance for industrial applications.

- Exceptional Hardness: With a Mohs hardness of 9, Edelkorund offers long life and high efficiency in abrasive processes.

- Temperature Resistance: Withstands temperatures over 2,000°C, ideal for high-temperature applications.

- Chemical Stability: Resistant to acids and alkalis, making it suitable for various materials.