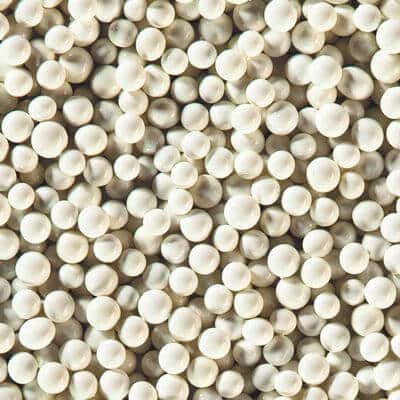

Our ceramic beads are among the highest-quality wet blasting media available. They enable precise surface treatment that is both efficient and gentle. Due to their exceptional hardness and durability, ceramic beads are the ideal choice for demanding industrial and technical applications.

Ceramic beads from Kuhmichel create perfect surfaces with a silky matt sheen. In terms of price, ceramic abrasives move in the upper segment, but have an extraordinarily long service life. We will be happy to help you.

PRODUCT FEATURES

| Typical physical properties | |

|---|---|

| Hardness | ca. 7 – 7,5 mohs |

| Grain shape | round |

| Melting point | ca. 2.100 °C |

| Specific gravity | ca. 3,8 g/cm3 |

| Bulk density* | ca. 2,1 – 2,4 g/cm3 |

*depending on grain size

| Typical chemical analysis | |

|---|---|

| ZrO2 | 61,98 % |

| SiO2 | 27,77 % |

| Al2O3 | 4,57 % |

| CaO | 3,47 % |

| Fe2O3 | 0,14 % |

| TiO2 | 0,34 % |

Available sizes

|

Metric Average grain size (µm) |

|

|---|---|

| 0 – 63 | |

| 0 – 125 | |

| 70 – 125 | |

| 125 – 250 |

|

Metric Average grain size (µm) |

|

|---|---|

| 250 – 425 | |

| 425 – 600 | |

| 600 – 850 | |

| 850 – 1180 |

Other grain sizes can be produced if required.

Blasting systems

Pressure blast machines

Vacuum blast machines

Wheel blast machines

Packaging

25 kg bags on 1t pallets

1 ton loose in a big bag

SPECIFICATION

AMS 2431/7

Why Choose Ceramic Beads from Kuhmichel?

With decades of experience in manufacturing and applying blasting media, Kuhmichel offers products that meet the highest quality standards. Our ceramic beads ensure:

- Outstanding Precision: Perfect for the gentle cleaning and finishing of sensitive surfaces.

- High Durability: Reduces consumption through multiple reuses.

- Versatile Applications: Suitable for a wide range of wet blasting techniques.

Applications:

Ceramic beads are used in various industries, including:

- Automotive Industry: Precise surface treatment of metal and aluminum components.

- Aerospace Industry: Gentle blasting for delicate parts and materials.

- Medical Technology: Cleaning and finishing processes for medical devices.

Benefits at a Glance:

- Gentle Processing: No material removal, making it ideal for sensitive workpieces.

- Optimal Surface Quality: Smooth, uniform results, perfect for subsequent coatings.

- Efficient and Cost-Saving: Thanks to long service life and reusability.